I half expected the boat to be engulfed by those little sandcastles that termites make when I came back to the boat shop this week after a nearly five month absence. No termites, thank goodness, just a lot of black mold. I welcome the mold. It comes with the incredible amount of rain we've received over the past several weeks. Rio Grande City is now a tolerable grassland rather than a post-apocalyptic dust bowl.

NASA was wonderful. I developed some algorithms for optimizing medical kits for spaceflight. And met real astronauts. The whole experience was incredibly inspiring. Fresh off this NASA high, I've re-committed to the boat project. This thing WILL GET DONE.

My brother came in on Sunday for a week of boat building. We actually spend the first few days battling the cockroaches (á la Stormship Troopers) that made themselves welcome during my long absence. We finally got around to some boat work on Thursday and will have the first layer of the chine glued in place by the time he leaves tomorrow afternoon.

My mentality re the boat project has shifted. I was beginning to feel paralyzed by the sheer size of the project-- by all the work remaining and all of the things that could possibly go wrong. I am now thinking no further than getting the chine laminated. Then I'll think no further than cutting the notches for the stringers on the bottomsides. Etc. This seems to be a more effective mindset, as I'm pretty sure I'll be able to get the chine in, and I'm pretty sure I can cut a few notches.

An acquaintance from college sent me this poem written by a boatbuilder. While at the moment I can't relate to the romanticization of boatbuilding in the body, I was particularly amused/struck by the first line:

And so it is, the boat has come to own you

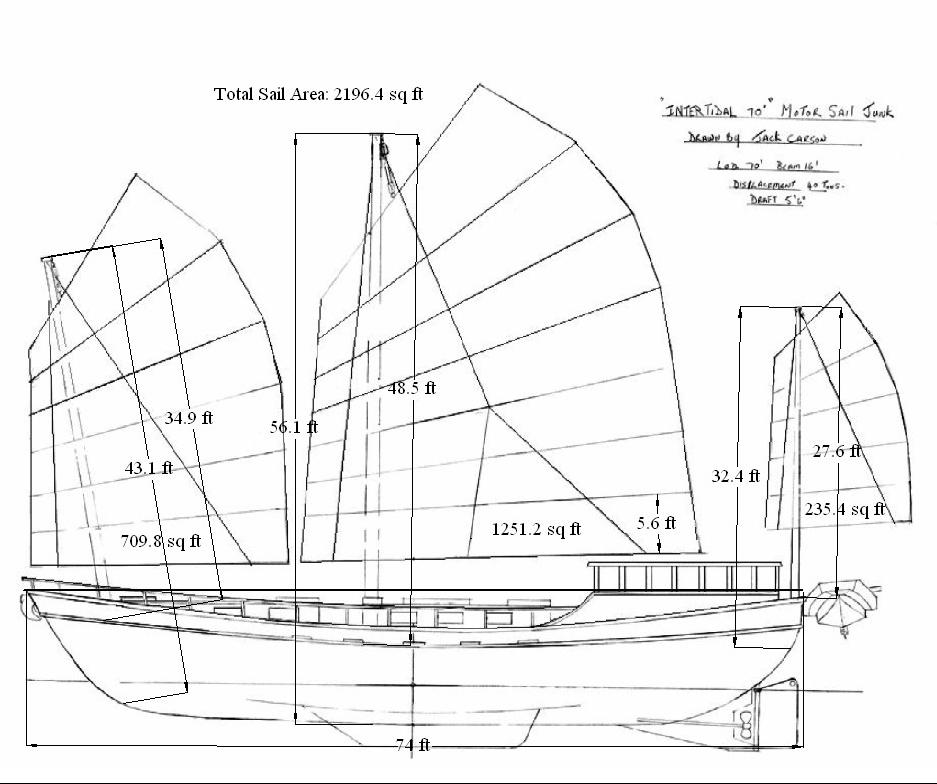

Indeed, building Luna came to own me. I resented my previous self who thought building a gigantic sailboat in small-town Texas was a good idea. Time away from Luna was exactly what I needed to build up the guts to finish her. Looking forward to the next few months of boat work!

NASA was wonderful. I developed some algorithms for optimizing medical kits for spaceflight. And met real astronauts. The whole experience was incredibly inspiring. Fresh off this NASA high, I've re-committed to the boat project. This thing WILL GET DONE.

My brother came in on Sunday for a week of boat building. We actually spend the first few days battling the cockroaches (á la Stormship Troopers) that made themselves welcome during my long absence. We finally got around to some boat work on Thursday and will have the first layer of the chine glued in place by the time he leaves tomorrow afternoon.

|

| This week at my house. Pro tip: Don't leave potatoes in cabinet for 5 months. |

My mentality re the boat project has shifted. I was beginning to feel paralyzed by the sheer size of the project-- by all the work remaining and all of the things that could possibly go wrong. I am now thinking no further than getting the chine laminated. Then I'll think no further than cutting the notches for the stringers on the bottomsides. Etc. This seems to be a more effective mindset, as I'm pretty sure I'll be able to get the chine in, and I'm pretty sure I can cut a few notches.

An acquaintance from college sent me this poem written by a boatbuilder. While at the moment I can't relate to the romanticization of boatbuilding in the body, I was particularly amused/struck by the first line:

And so it is, the boat has come to own you

Indeed, building Luna came to own me. I resented my previous self who thought building a gigantic sailboat in small-town Texas was a good idea. Time away from Luna was exactly what I needed to build up the guts to finish her. Looking forward to the next few months of boat work!

|

| The not-so-little brother and I. |

|

| Slinging epoxy. |

|

| The first chine piece glued in place. |